End Mills

End Mills are being manufactured both in Brazed Carbide Tipped and Solid Carbide type. They have a wide application in the engineering industry engaged in machining activity. These end mills are being manufactured in low and high helix flutes and in equal and unequal distribution depending on application and material to be machined. We can provide 2,3,4,6 & 8 fluted end mills both in Brazed and Solid Carbide. Helix is restricted in Brazed Carbide End Mills.

Orient Tools stock an extensive range of Standard solid Carbide, Cobalt and High Speed End Mills all INDIA manufactured to the highest standard. Our End Mills are all available with same day shipping at affordable prices.

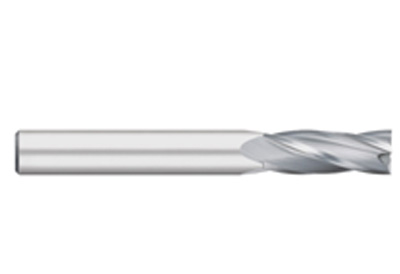

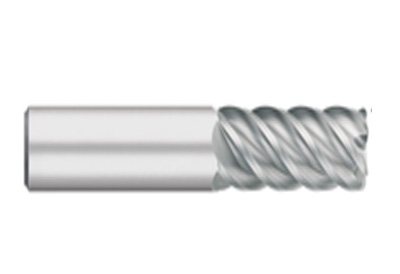

An End Mill is a type of milling cutter designed to be held by the shank on one end in order for it to cut with the opposite end. The advantage to an End Mill is that, unlike any other type of milling cutter, it is capable of cutting on the periphery, the face or the end of the cutter. At orient, our offering of End Mills is Solid Carbide Roughing & Finishing Mills to application and material specific tools employing the latest geometries and coating technologies all resulting in improved efficiency and productivity for you. The number of flutes can range from two to eight. The fewer flutes offer the most efficient chip removal, but a higher amount of flutes provide a smoother finish. The End Mill’s helix angle is also important. Most general purpose End Mills have a 30-degree helix angle because it is halfway between “slow” (low-angle) and “fast” (high-angle) helix End Mills.

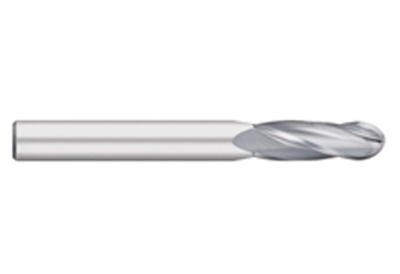

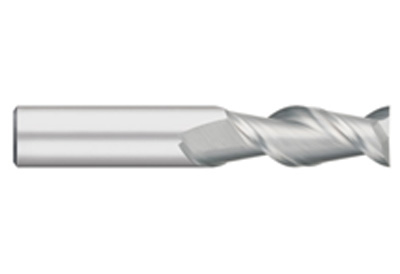

Specific projects require special styles of End Mills. Ball Nose End Mills are best for machining round bottom holes and complex contoured surfaces. Square Nose End Mills have square ends and are best for slotting, profiling, and roughing. Corner Radius End Mills have a square end with rounded corners on the cutting edges to reduce chipping. Double-ended End Mills have the same cutting edges and styles on both ends, doubling the tool’s life compared to Single-ended End Mills.

Cutter material is an important consideration when selecting an end mill. Carbide End Mills can run at higher speeds than high-speed or cobalt steel, it is also more resistant to wear and can be used at high cutting temperatures. Cobalt Steel End Mills resists abrasion and high cutting temperatures, and has higher feed rates than High-speed Steel. High-speed Steel End Mills are compatible with a variety of materials and is typically used for less demanding jobs.

An End Mill’s end cut type can either be center cutting or non-center cutting. Center-cutting end mills can create three-dimensional shapes and profiles, and make plunge cuts similar to a drill bit. All Carbide End Mills are center cutting. Non-center-cutting End Mills are suitable for peripheral milling and finishing, but cannot be used to make plunge cuts.

Orient Tools end mills offer a variety of coatings. Some end mills are uncoated, while others are coated with finishes to enhance performance. Most finishes extend the life of the End Mill and allow higher cutting speeds and feed rates.

Features:

- Consistent performance

- Durability

- Efficient Cutting

Micro Ball End

Corner Radius

Metric

Double End Ball

3,5, & 6 Flute

3, 5, & 6 Flute Corner Radius

For Aluminum

Variable Index

Variable Index Corner Radius